Address

Trio Supply Chain Solutions, LLC 2905 Tech Center Santa Ana, CA 92705

Address

Trio Supply Chain Solutions, LLC 2905 Tech Center Santa Ana, CA 92705

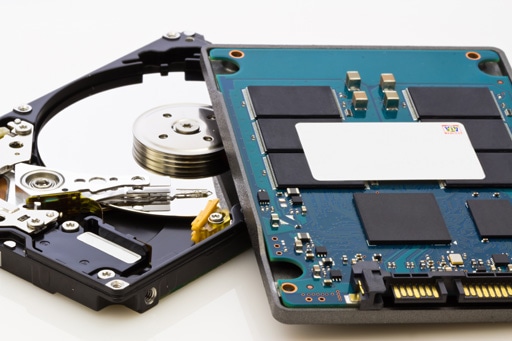

Measuring vendor quality isn’t a one-shot deal. It requires a continuous effort. We review our vendor performance on an ongoing basis. We regularly score aCustomers expect that every part is what the vendor says it is, performs at the desired level, and won’t fail in the near future. Trio SCS works to ensure the highest level of testing. We work with a global network of approved third-party specialists whose core business is testing CPUs, LCDs, mainboards, graphics cards and optical drives to make sure components live up to that promise. As experts in hard drive testing, we fully test hard drives in-house.

We validate all serial numbers, schematics, and bill of materials with the original equipment manufacturer to ensure that each and every part is authentic and to guard against counterfeiters. In this way, we help ensure high quality and boost customer satisfaction. Hard drives are comprised of many components, and overall quality is no better than the weakest link. We provide comprehensive diagnostic testing of hardware characteristics such as motor timeouts, hard and soft errors, and full data erasure to certify the quality of our hard drives.

We perform extensive physical inspections of all parts. Not only do we look at physical condition and breakage, we also verify the authenticity of packaging, manufacturer’s PIN, date codes, moisture barriers, connectors, boards, and trays. We compare part markings to known examples.

When sourcing hard-to-find, end-of-life parts, you may need to purchase parts that have been previously used. We evaluate the remaining lifespan of each and every part to give you full transparency into a part’s condition so you can appropriately set customer expectations.

A hard drive failure is a tremendous risk for customers. At best, they’ll need to spend valuable time restoring data; users can even lose their data altogether. Predictive failure testing determines how likely it is that the particular HDD will fail based on the drive’s performance to minimize risks for customers.

To ensure that their brand meets expectations, many customers have requirements for hard drive testing above and beyond the OEM’s specifications. We can develop test scripts that ensure that the HDDs meet your specific criteria. If you have no particular requirements, we test to industry standard specifications.

Static electricity is one of the primary threats to electronic components. We perform all testing in a fully electro-static discharge (ESD) protected environment designed specifically to prevent ESD, shock, and moisture from the time the component arrives in our facility until it’s shipped to the customer.